Unlocking Business Growth with Liquid Injection Molding Silicone

Introduction

Welcome to Nolato.com! In this article, we will delve into the world of liquid injection molding (LIM) silicone and explore how it is revolutionizing the electronics industry. If you're looking for high-quality solutions that can help your business gain a competitive edge and drive growth, you've come to the right place.

Understanding Liquid Injection Molding Silicone

Liquid injection molding silicone is a versatile material used in various industries, particularly in the electronics sector. It offers exceptional durability, flexibility, and resistance to extreme temperatures and harsh environmental conditions.

At Nolato, we are at the forefront of harnessing the potential of liquid injection molding silicone to develop cutting-edge components for the electronics industry. Our team of experts combines state-of-the-art technology with extensive knowledge and experience to deliver superior products tailored to your specific needs.

The Advantages of LIM Silicone in Electronics

1. Design Flexibility: Liquid injection molding silicone enables the creation of intricate designs and complex geometries, providing designers with unparalleled freedom to innovate. This flexibility is crucial in meeting the ever-evolving demands of the electronics industry.

2. Enhanced Durability: Nolato's liquid injection molding silicone solutions are engineered to withstand extreme conditions, ensuring longevity and reliability for electronic devices. Whether it's exposure to high temperatures, moisture, or chemicals, our products maintain their performance even in the harshest environments.

3. Exceptional Electrical Insulation: Electrical insulation is vital in electronics to prevent short circuits and ensure safe operations. Liquid injection molding silicone exhibits excellent dielectric properties, making it an ideal material for applications requiring high voltage resistance.

4. Optimized Production Process: Our advanced liquid injection molding technology allows for efficient production, reducing lead times and costs. With our optimized manufacturing process, we can swiftly deliver large quantities of high-quality components to meet your business requirements.

Nolato's Commitment to Quality and Innovation

At Nolato, we aim to be your trusted partner in driving business growth. Our dedication to quality, innovation, and customer satisfaction sets us apart from the competition. By staying at the forefront of technological advancements and industry trends, we continually develop cutting-edge liquid injection molding silicone solutions that address the specific challenges faced by the electronics sector.

Our Range of LIM Silicone Products for Electronics

1. Silicone Keyboards and Keypads: Our liquid injection molding silicone keypads offer superior tactile feedback, durability, and resistance to wear. They are ideal for use in various electronic devices, such as remote controls, medical devices, and industrial equipment.

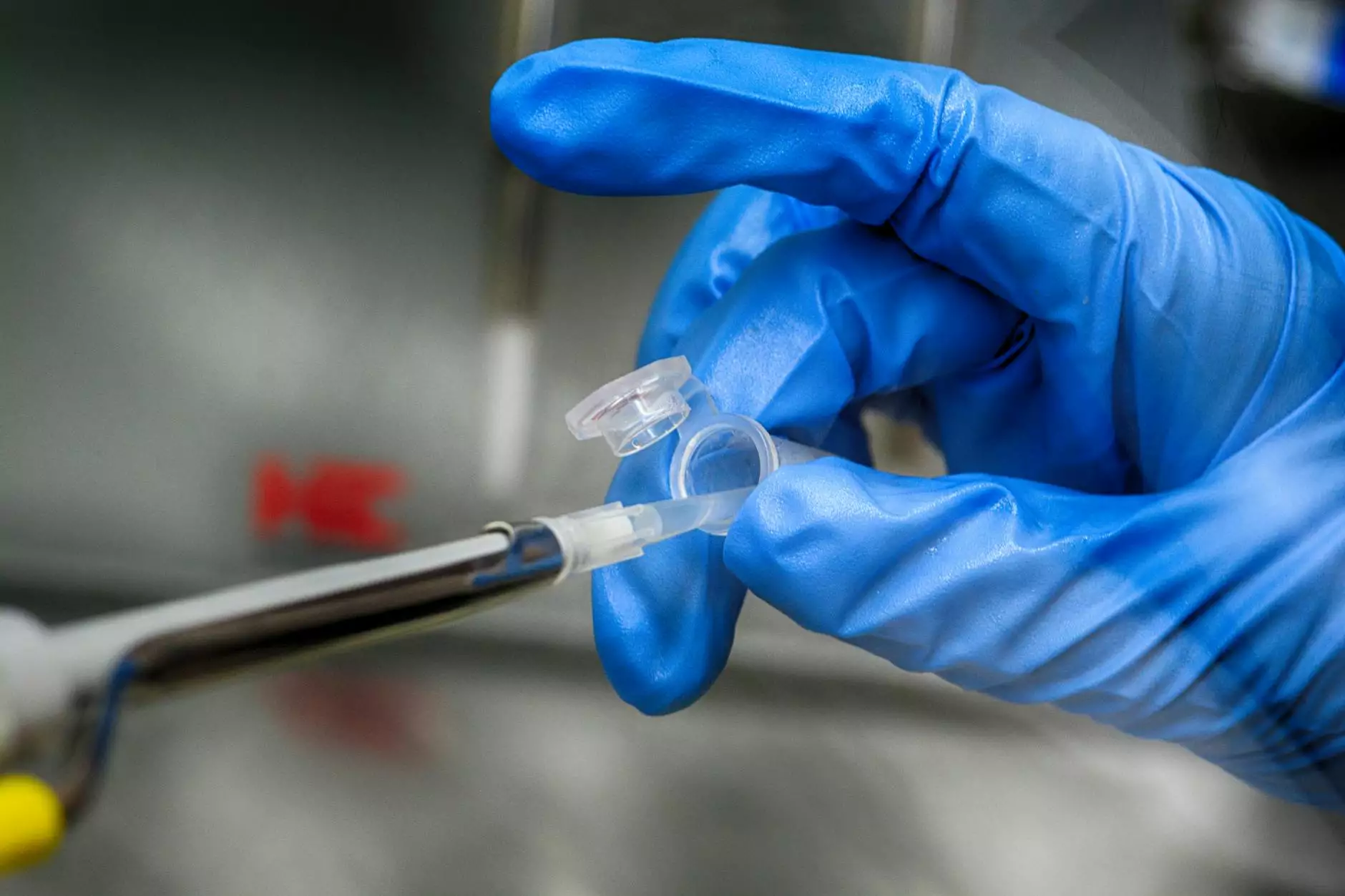

2. Sealing Solutions: Nolato's liquid injection molding silicone seals provide excellent protection against moisture, dust, and other contaminants. These sealing solutions are crucial in ensuring the longevity and performance of sensitive electronic components.

3. Gaskets and O-Rings: Our precision-engineered liquid injection molding silicone gaskets and O-rings offer exceptional resilience and sealing capabilities. They are widely used in electronic enclosures, connectors, and automotive applications.

4. Connectors and Cables: Nolato's liquid injection molding silicone connectors and cables deliver superior reliability and connectivity even in demanding environments. They are designed to withstand extreme temperatures, UV radiation, and chemical exposure.

Conclusion

As the electronics industry continues to evolve, businesses must adapt and embrace innovation to stay ahead. Nolato's liquid injection molding silicone solutions empower companies to unlock their true growth potential by harnessing the advantages of this revolutionary material.

By combining state-of-the-art technology, extensive expertise, and a commitment to quality, Nolato has established itself as a leading provider of liquid injection molding silicone solutions for the electronics sector. Our comprehensive range of products caters to diverse needs, ensuring that your business can thrive in an ever-changing market.

Partner with Nolato today and experience firsthand how our high-end liquid injection molding silicone solutions can elevate your business to new heights. Contact us now to discuss your requirements and discover the endless possibilities that await.